In order to freeze foodstuffs without modifying their organoleptic qualities, it is necessary to apply a rapid lowering of their temperature lower than or equal to -18°C, so as to limit the time of stay of the product during the phase of maximum crystallization, included between -1°C and -5°C, according to the foodstuffs. This freezing process is called IQF (Individually Quick Frozen).

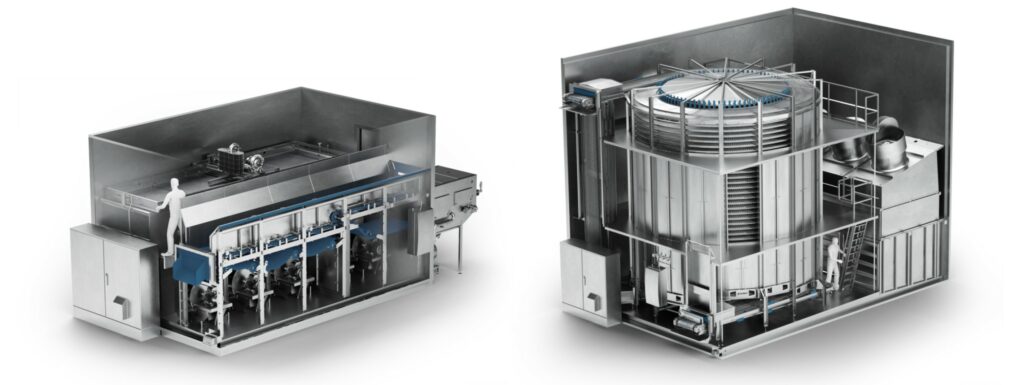

Generally for this process, a dynamic freezing tunnel with conveyor belt and fluidized bed is necessary. It allows individual freezing of small foods such as peas, cauliflower florets… by suspending the food in an ascending cold air stream (-30 to -50°C) allowing a very fast and individual freezing of pieces or particles, without sticking them.